Technologies

Our technologies

The i-FAB is a concrete example of a smart factory and demonstrates the benefits that digital technologies can bring to operations management. Inside the i-FAB it is possible to interact with various technologies and get to know the whole range of pillars of today's fourth industrial revolution.

In particular, the i-FAB offers the possibility to experiment with:

IOT (internet of things)

This represents the evolution of the network where "things" (objects) become recognisable and acquire intelligence. In the i-FAB, the boxes containing the components to be assembled alert the operator that they need to be replenished. The products to be assembled are equipped with RFID transponders that make them recognisable and traceable. The movements of the operators are monitored in order to optimise the layout.

⠀

⠀

Integration

Software enables the factory to be connected along the supply chain, providing information both to suppliers, so that they are aware of the stock of components, and to customers to enable them to monitor the progress of the order. In addition, there are applications that allow monitoring of the factory state by giving prompt warning of possible downtimes and analysis of historical data to understand possible causes of non-quality.

Virtual reality

Virtual reality models allow you to navigate inside the factory even before it has been built in order to work out all the spaces necessary for the movement of operators, equipment and products. Operators can be trained within virtual reality models on the tasks they will have to perform on the line.

⠀

⠀

⠀

Big data & Analytics

Data is collected from different sources (e.g. operators, RFID transponders placed on the product to be assembled, work tools, monitoring software) and aggregated into one large data set. This requires unconventional techniques to extract, manage and process information within a reasonable time.

⠀

⠀

⠀

⠀

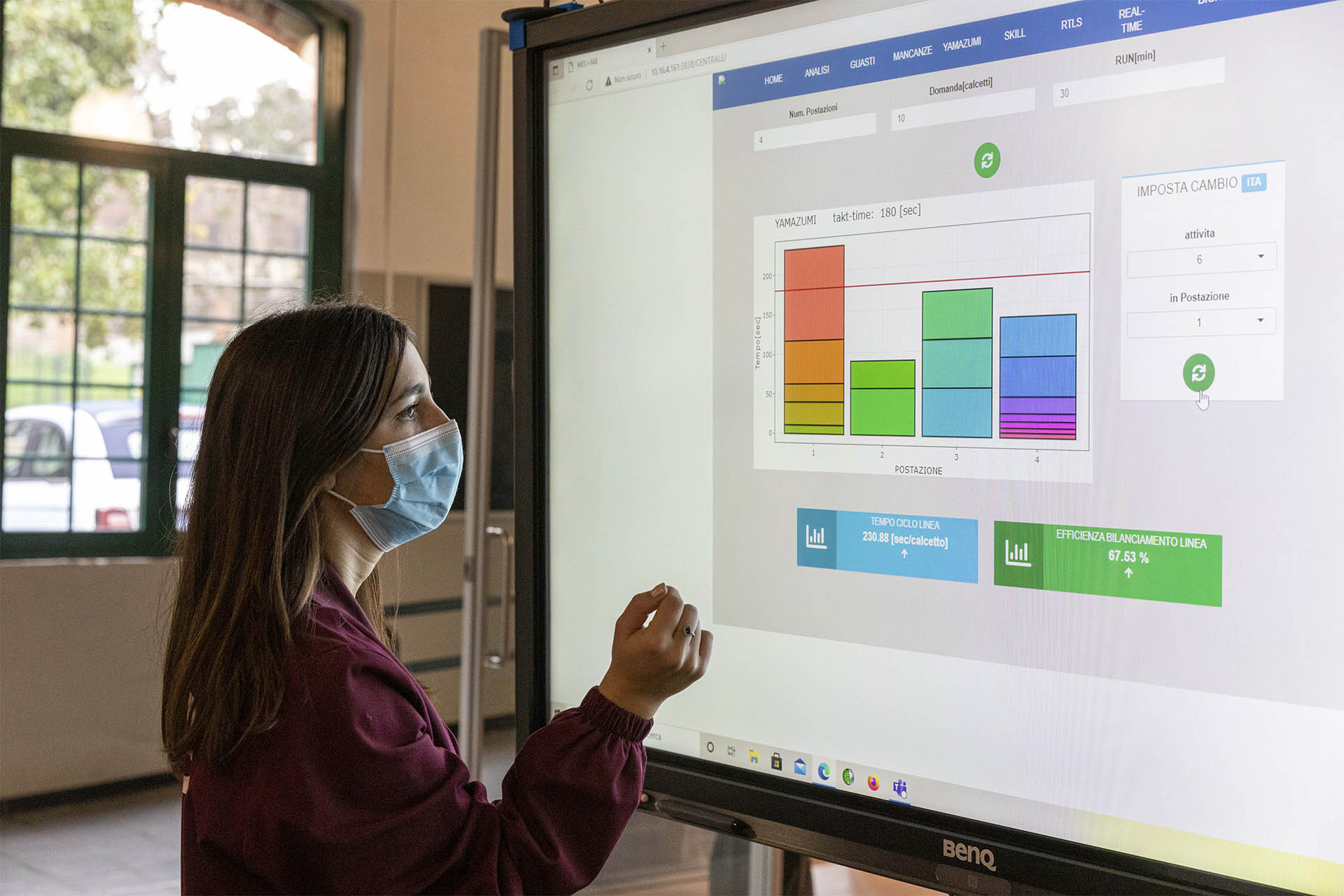

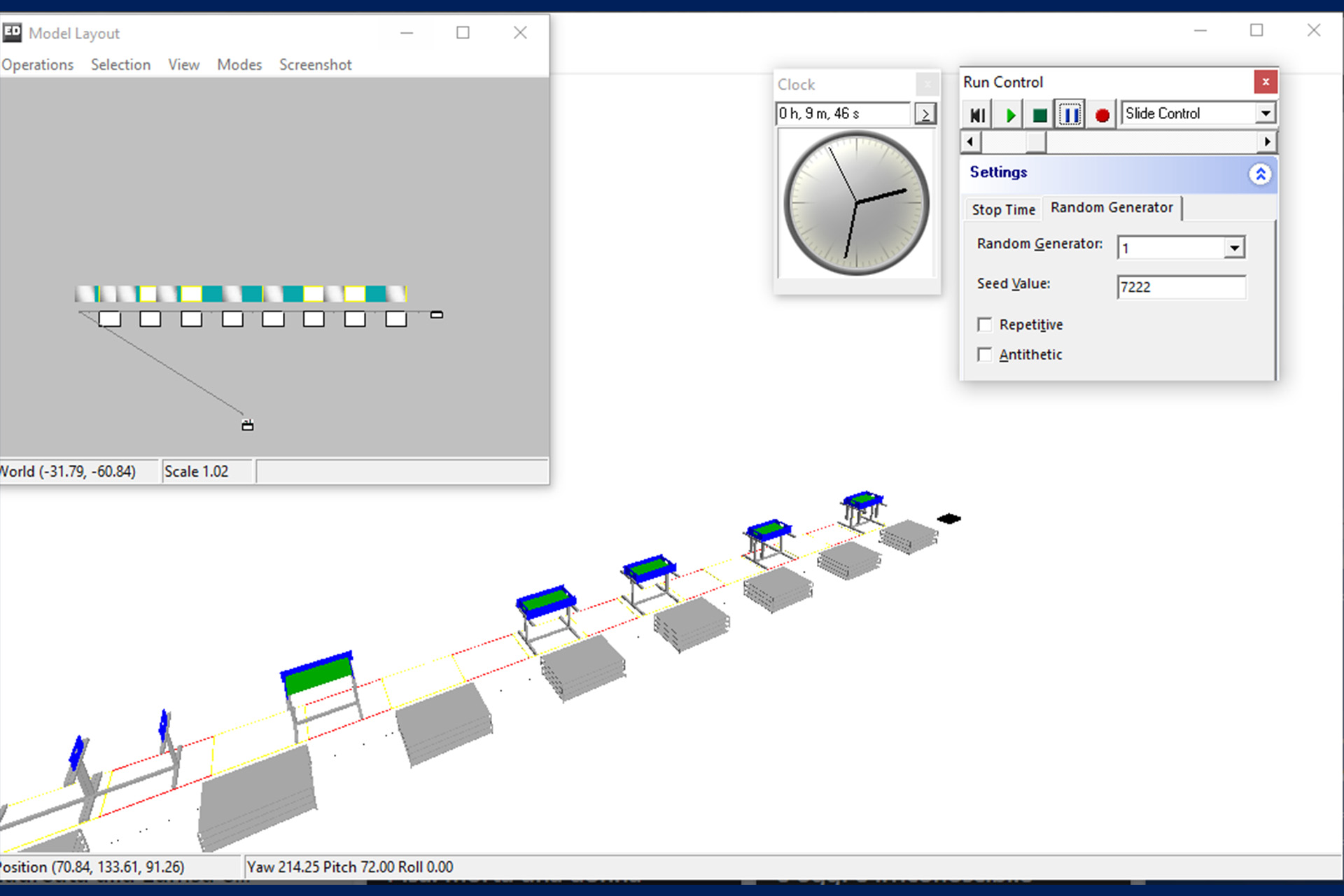

Simulation

Digital representation of the physical factory, makes it possible to design the production line and predict its behaviour in the future, so as to have an important decision support even during operation.

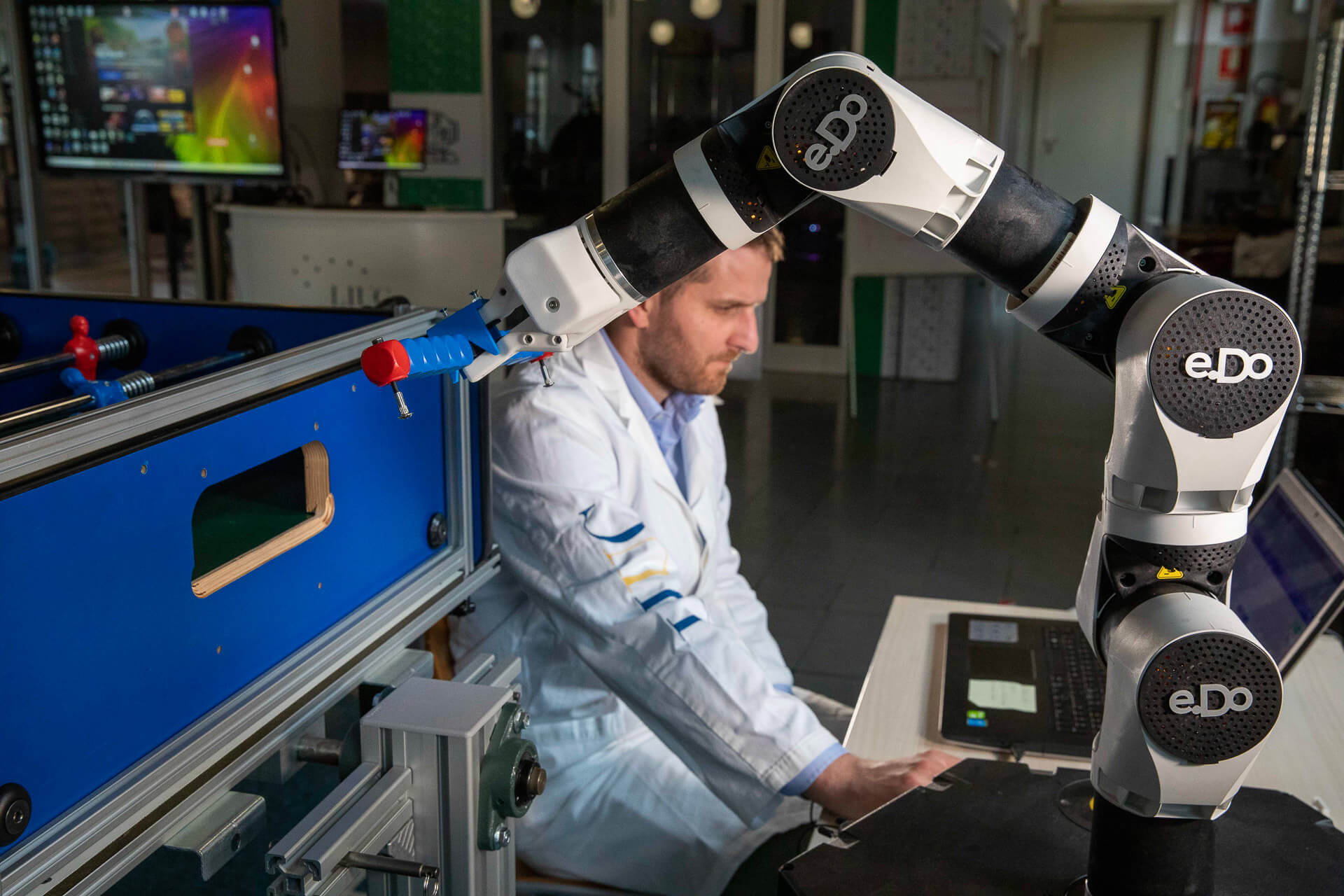

Autonomous robots

These robots are capable of detecting their environment and human intervention. The robot can perform assembly and handling operations on products and components in total safety and in cooperation with the operator.

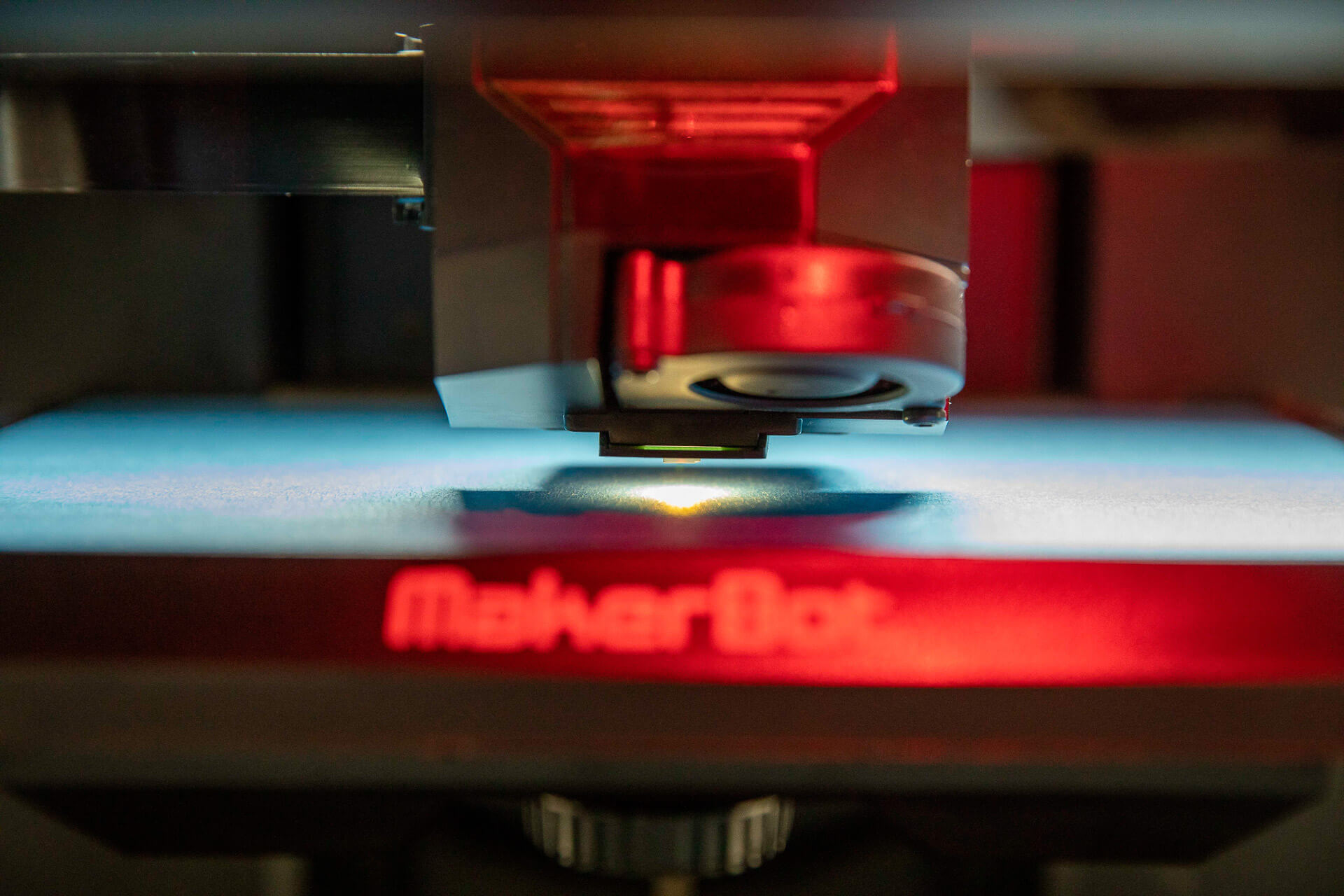

Additive manufacturing

3D printing technology is used to produce small series and highly customised components requested ad-hoc by customers, or to develop tools and equipment to facilitate assembly.

⠀

Cloud e cyber security

Considered a fundamental prerequisite within i-FAB for interconnecting machines, people and equipment, this is not tangible and visible but present in the technological infrastructure.

⠀

⠀