Knowledge and technology transfer is our forte. Through direct experience, we try to highlight the problems and enhance the possible benefits that can be obtained in implementing lean methodologies and the technologies of the 4.0 paradigm.

model factory

Cattaneo University

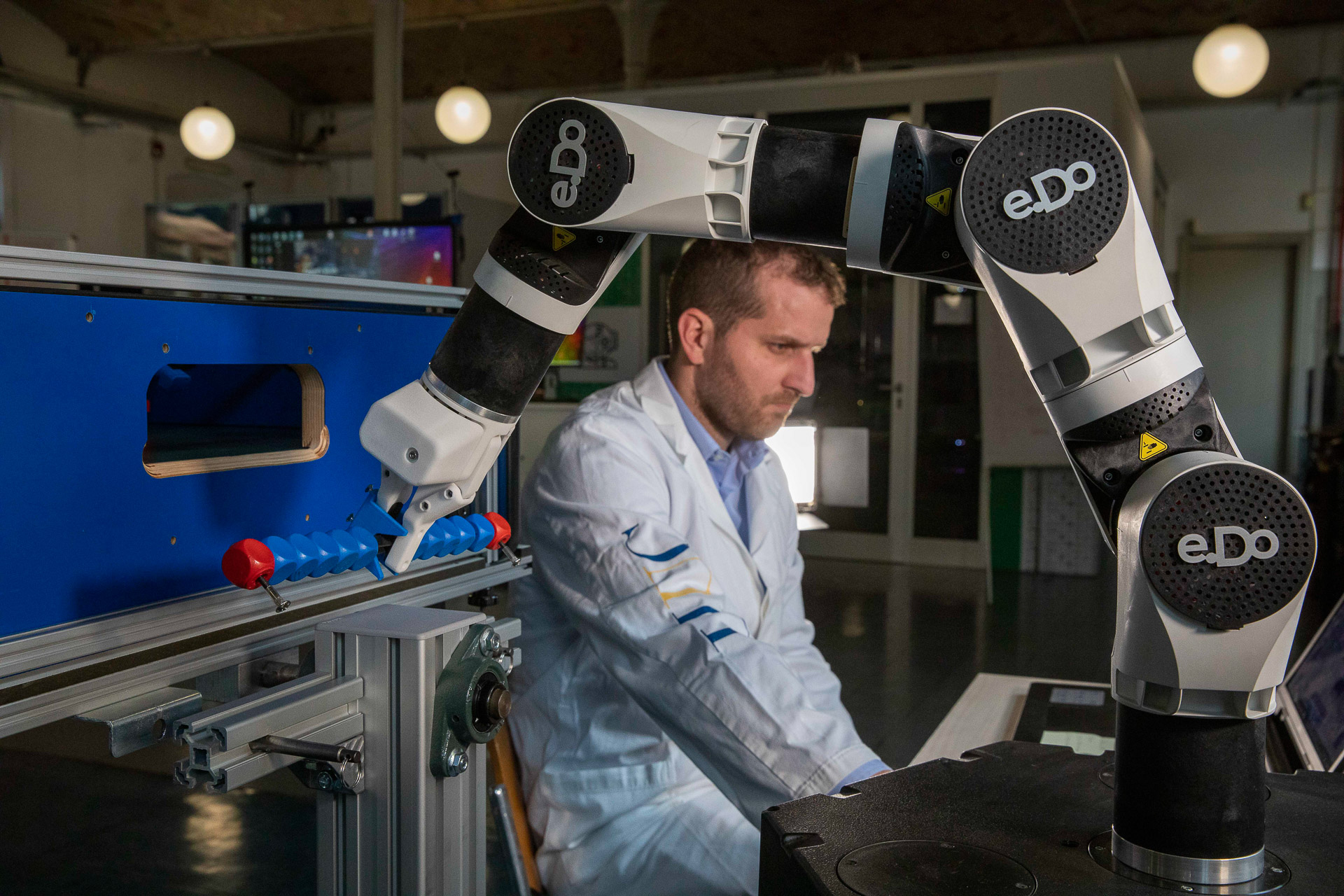

The Lean and Industry 4.0 model factory

An innovative classroom in which to get involved with "learning by doing", an analogue example of a lean, digital factory and an experiential laboratory in which to conduct research.

The product

Within the i-FAB laboratory, the process of assembling and disassembling a table football game is simulated on a 1:1 scale. Table football is a product made up of numerous components of various shapes, sizes and weights, which make it possible to realistically simulate the complexities typical of logistics-production systems.

⠀

The process

The i-FAB production process is a parts production process: the table football product can be assembled and disassembled as the original components are distinguishable and do not change in nature during the manufacturing phase. The disassembly phase feeds the assembly phase, thus enabling simulation of the different production steps.

Technologies

The i-FAB is a concrete example of a smart factory, demonstrating the benefits that digital technologies can bring to operations management. Inside the i-FAB it is, in fact, possible to interact with various technologies and get to know the whole range of pillars of today's fourth industrial revolution.

⠀

⠀

⠀

Presentation of I-FAB

Testimonials

Andrea Greggio

Head of Engineering and digitalization - Datwyler

Federica Bergamin

Alumna of the course "Lean in Production"

Chiara Monetti

Alumna of the course Smart Factory

Alessandro Cerutti

Production Manager - Lesta srl

Gianmarco Regaldi

Project Manager - Ponti

Marco Falletta

Alumnus of the "Basics of Data Analytics" course